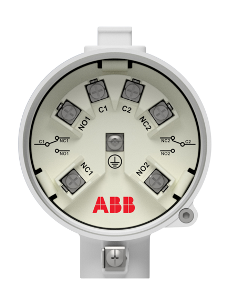

LMS200

.jpg)

Overview

The LMS200 consists of two snap action switches operated by a precision actuation mechanism. The actuation mechanism consists of two cams arranged on a spindle assembly. A rod magnet is internally mounted to a spindle assembly in such a way as to cause the spindle to rotate when a magnetic field of proper orientation passes near the switch. A magnetic KM26 float passing by the LMS200 in either the upward or downward direction will cause the switch to change states. After the float has passed, the switch will remain in its respective state until the float passes the switch going in the opposite direction. The action of the switch is break before make.

The unique magnetic coupling action eliminates the need for seals, diaphragms, springs, or torque tubes. There is no physical contact between the switch and the process. Magnetic coupling also eliminates the necessity of process connections and insures total isolation from the process.

Data

- 10 amps rated DPDT switch (NO or NC contacts)

- Unique concept of magnetic coupling, eliminating direct contact with process

- No process piping or valves required

- Easy mounting and adjustment; only small screwdriver required

- Trip point infinitely adjustable without changing process piping

- Vibration resistant

- Compact design

- Suitable for high temperature applications

- Industrial Explosion Proof IP66/67 and NEMA4X enclosure with ATEX/IECEx, FM US and Canadian approvals

My Measurement Assistant

My Measurement Assistant